Acoustic foam - flexible and effective sound suppression

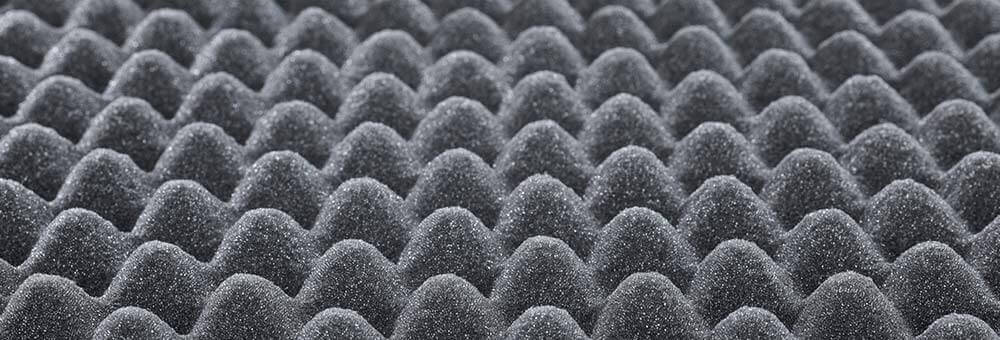

Different models are available to change the acoustics of a room according to your own wishes or to isolate disturbing noise sources. The most commonly used material is acoustic foam, which cannot be compared to conventional foam. Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. It is characterised by both light workmanship and high application efficiency. Acoustic foams are ideal for soundproofing, acoustic treatment, sound insulation and sound suppression. The surface of acoustic foam panels can be profiled to affect the properties of the sound. For example, a pyramid profile and an egg crate profile differ not only visually, but also acoustically. This makes foam an extremely flexible and attractive raw material. In various colours, foam also provides interesting compositions in the interior design.

How does acoustic foam work?

Due to the special open-pored material structure of acoustic foam, the incoming vibrations of the air particles, i.e. the sound, are slowed down or suppressed. As a result, noises or only certain frequency ranges are absorbed. This is particularly useful for sound-absorbing measures to improve room acoustics, such as in an auditorium or concert halls. When absorbed through porous materials, sound energy is converted into heat energy, which, however, remains unnoticeable. The conversion occurs through friction when the excited air particles penetrate and move in the pores of the acoustic foam. The more open and deep the pores of the acoustic foam are, the more effectively this friction process can take place and sound can be absorbed. Soundproofing elements made of acoustic foam can significantly reduce the noise level in the room and suppress noise.

Types of acoustic foam

Generally, acoustic foam can be divided into three categories. A distinction can be made between acoustic foams made of polyether, polyester and duromer acoustic foams. We have summarised the properties of the different types for you in a separate article (polyether, polyester, duromer acoustic foam). If you have any questions about the applications of the individual acoustic foams, we will also help you free of charge in our aixFOAM shop or on our customer hotline.

How can you recognise high-quality acoustic foam?

As a rule, any porous material absorbs sound. Quality goods - such as the aixFOAM acoustic foams - come with the crucial advantage, however, that you can plan and predetermine the soundproofing or acoustic treatment precisely. Because the specially developed products have a special material structure that absorbs the sound and can be planned reproducibly. With conventional foams or other porous materials, this can be a game of chance.

Acoustic foam and fire protection

High-quality acoustic foams also have good fire protection properties as building materials and ensure the necessary level of safety in emergencies, especially when renovating buildings. Many of our aixFOAM products are not only flame-retardant, but also comply with fire protection class DIN4102 B1 - one of the most important fire protection standards in the construction sector. They are therefore flame retardant.

Our recommendation for the right fire protection solution: Find out about the fire protection requirements of your construction project and ask our experts. We help you to choose the right material for your requirements.

Acoustic foam and density

It is not necessary to specify a density for acoustic foam - and it can even be misinterpreted. A higher density does not necessarily mean that there is better absorption of sound waves. It is therefore not an important factor for effective noise insulation. For example, a high-quality foam panel made of duromer foam has a very low density, but the acoustic effect is extremely high in comparison. We therefore state the sound absorption levels for each of our acoustic foams and not the density.

Easy modification and installation

High quality acoustic foams are impressive materials, especially when being reworked. They can be modified with standard household tools such as an electric kitchen knife, a carpet knife or a band saw. This makes our aixFOAM foams a particularly flexible solution.

For straight cut edges, it is advisable to lay a roof batten or a square-profile batons directly on the foam panel for safety reasons and then carefully cut along it. So that you do not experience any nasty surprises, it is best to check beforehand on a sample piece of acoustic foam whether your cutting tool is really suitable.

Many of our aixFOAM acoustic mats are available with self-adhesive backs for the easiest possible installation. The foams are also perfect as a free-standing solution, in a practical set with high-quality acoustic frames, wall cassettes and special mounting accessories. When measuring the degree of absorption, they achieve very good values and also visually enhance the room.

Acoustic foam directly from the manufacturer

As a manufacturer with 60 years of experience in the assembly and processing of quality acoustic foams, we at aixFOAM are your partner when it comes to soundproofing and sound insulation. In our foam warehouse you will find many varieties of modern, trendy colours and unusual shapes. Whether profiled acoustic elements, such as pyramid foam or egg crate foam, absorbers with a textile surface, broadband absorbers, insulating mats or special ceiling sails – we offer the best solution for every application in technical acoustics and room acoustics.