Individual service requests

Are you a major customer? Do you need different delivery quantities than in the shop? Do you have special requirements for packaging or special shipping and delivery conditions? Talk to us!

To contact page

Are you a major customer? Do you need different delivery quantities than in the shop? Do you have special requirements for packaging or special shipping and delivery conditions? Talk to us!

To contact pageOptics

Smooth surface

Structured surface

Felt surface

Noise source

Air-borne sound, high frequency

Air-borne sound, medium frequency

Structure-borne sound

Air-borne sound, low frequency

Matching products: Reset Filter

Classic Line

Classic sound absorbers for less noise, reverberation and drone

Professional Line

Sound absorber with soundproofing and flame protection Plus, chemically resistant

Felt-laminated acoustic elements, classic acoustic foams and much more can be found in our CLASSIC LINE.

Higher fire protection, more design, printable elements and much more can be found in our PROFESSIONAL LINE.

Sound absorbers inside the loudspeaker box reduce casing vibrations, unwanted sound reflections and passage noise and improve the loudspeaker sound. Especially when building loudspeakers, the loudspeaker dampening should be planned in advance. Subsequent dampening is relatively expensive and therefore should be avoided.

In order to prevent these reflections and sound passage to the outside, the casing should be filled with acoustic wadding or acoustic foam flakes or clad with open-pore sound insulation mats, which absorb the sound waves. Sound absorbers such as the acoustic sound insulation mat with smooth surface, the acoustic panel with robust textile surface or the nubbed foam are idea for technical insulation.

Sound insulation mats should be used in particular for loudspeakers with bass reflector pipes because unlike flakes or wool they are not pushed outward over time.

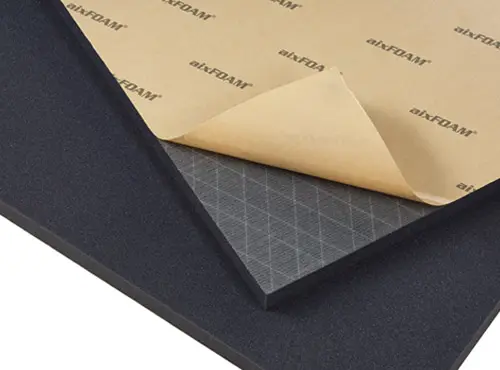

For a particularly simple application, aixFOAM sound absorbers are fitted with practical self-adhesive kit that greatly simplifies installation in loudspeakers.

Our thin and flexible heavy acoustic foil is ideally suited for this. The heavy foil has an above-average surface weight and thanks to the self-adhesive reverse can quite easily be stuck to the inside of the loudspeaker.

If necessary, the heavy acoustic foil can also be combined with porous absorbers so that a highly effective sandwich element is created to dampen the loudspeakers, which has an anti-drumming effect for the casing and also removed sound distortions and passage sound.

It is also possible in the aixFOAM product configurator to order your sound absorbers directly fro the factory with a heavy acoustic foil lamination. Simply choose the corresponding option for this.

This is achieved most simply with an underlay made from heavy acoustic foam, which prevents the transmission of structure-borne sound through the floor. The sound insulation panels should then also be covered with a panel of stone (granite, slate, etc.) or wood in order to prevent the loudspeaker from sinking into the absorber. The sound insulation panel absorbs the vibrations from the loudspeaker and noise does not reach other rooms.

Alternatively, for large speaker systems a separate riser can be built, which should also be decoupled from the floor sufficiently. In this case, ensure that rigid structural elements are not in direct contact with the floor.