Effective sound insulation for appliances and equipment construction

Because of their design and technology, lots of appliances and equipment – even basic domestic appliances such as washing machines – generate a considerable noise level that makes effective sound insulation essential. Medical appliances, construction equipment or electrical appliances are also common noise sources.

What causes noise in appliances and equipment construction?

Apart from the usual motor noises and operating noises, which are perceived as direct sound (air-borne sound), the design of many appliances is a reason for their volume. Frequently, the casings of the appliances have large metal or plastic areas, which when operating easily start to vibrate and thus become sound conductors (structure-borne sound). If the structure-borne sound is then converted into air-borne sound, a loud drumming can be heard.

Appliances such as washing machines generate strong vibrations which without soundproofing are transferred to the building. Read more about this in our aixFOAM knowledge article (German).

Read more (German)

Why is sound insulation so important in appliance construction?

Every-day noise is one of the largest risk factors for human health. A permanently high sound level not only can damage hearing, but can also lead to stress and heart and circulatory diseases. Consequently there are precise regulations for noise insulation on appliances and plant in many areas of use, e.g. the machine noise protection ordinance, the workplace directives or noise provisions for residential areas (Federal Emissions Protection Act). In order to fulfil these regulations and to protect health, sound insulation is essential on many appliances.

How does sound insulation on various appliances work?

With regard to sound insulation in appliance construction, in general a distinction is made between two measures for reducing noise – soundproofing (sound insulation) and sound dampening.

Measures for soundproofing are suitable for anti-drumming of appliances in order to stop the transmission of structure-borne sound. Sound insulation mats with a high surface and intrinsic weight should be used here, ideally absorber made from heavy acoustic foam such as the heavy acoustic foam HEAVY Duty Tec or the membrane absorber SILVER Silence. The very flexible heavy acoustic foil SH0131 is ideal for strengthening the material of appliances and casings, thereby reducing material vibrations.

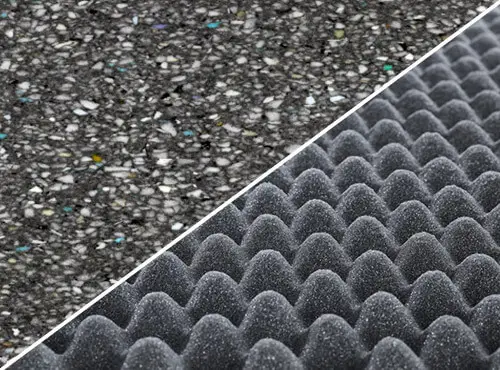

Lighter absorbers such as the traditional nubbed foam are not suitable for blocking structure-borne sound but are used in sound dampening. In order to dampen direct sound (air-borne sound), the sound absorbers made from open-pore acoustic foam are particularly recommended. Sound waves can penetrate deep into the material and thus can absorb the noise.

Heavy weights made from heavy acoustic foam are the best choice against structure-borne noise from appliances. By contrast, porous sound absorbers such as nubbed foam or flat sound insulation mats such as the sound absorber SH0011 effectively dampen air-borne sound.

Sound insulation in electrical appliance production and construction equipment

On modern electrical appliances, suitable sound insulation is often integrated by the manufacturer. For older electrical motors, the noise emissions may still be considerable, however, and this makes necessary to subsequently improve the soundproofing. Depending on the type and origin of the noise (air-borne or structure-borne sound?), suitable acoustic elements can be used – as described in the previous section.

When using construction equipment, the noise protection ordinance, which regulated the permitted sound pressure level of the equipment, applies. Certainly, low-noise construction equipment is now available on the market, which makes a comparable retrofitting of soundproofing unnecessary, but for older construction machines in particular this may be the only way to comply with the required values.

If the noise emissions of construction machines and equipment are above the sound level permitted by the noise protection ordinance, the construction equipment noise must be minimised by effective sound insulation measures.

Sound insulation for medical appliances

Because of their size and often extensive plastic cladding, medical equipment, for example MRI scanners, frequently tend to vibrate. In order to dampen these and to improve the sound insulation for pneumatic, diagnostic and other medical equipment, it is necessary to increase the surface weight of the machine casings. Our anti-drumming mats made from heavy acoustic foil SH0131 are particularly good, as they are very flexible and easy to work.

Our membrane absorbers SILVER Silence are suitable for even more effective soundproofing as well. Thanks to a protective aluminium foil, they are also washable, protected against spray and dirt, and thus are perfect for complying with the high hygiene requirements in clinics and medical areas.

In the medical area in particular, it is important to ensure the lowest possible noise emissions for patients. Sound insulation reduces noise from medical appliances.

Why is aixFOAM sound insulation the best choice for soundproofing your appliances?

Because of our 60 years' experience and the constant optimisation of our production processes, we have succeeded in developing flexible, robust and simultaneously highly effective sound absorbers.

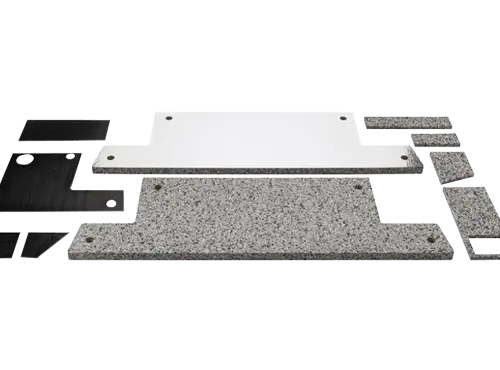

As a modern manufacturing company, we are not only able to offer you standard sound insulation panels, but can also make individual, tailored products for you for the perfect fit in your appliances. Simply tell our service team your needs.

Using precise CNC technology, we at aixFOAM make sound insulation for a perfect fit in your appliances.

aixFOAM sound absorbers reduce noise and material vibrations. They are available in different fire protection classes and material thicknesses. Choose your favourites from several surface profiles. Different surface laminations make aixFOAM sound insulation mats resistant to liquids and dirt and the practical self-adhesive kit simplifies installation, even in difficult locations.

Production

standardised or

individual

Surfaces

profiles to

choose from

Heights

different heights

can be selected

Installation

multiple

options

Fire protection

in different

classes

Protection

against dirt

and liquids

Now it's your turn: Get the right sound insulation for your appliances!

Now choose the right sound insulation from our aixFOAM products for the appliance construction or use our free advice service. Our experts will support you with your projects and help you find the optimum solution for your requirements.

The aixFOAM technical planners can be contacted by telephone or email.

Free advice

This is where you can find the right sound insulation for the application in appliance production.

To the products