Sound insulation for machinery and plant

What causes noise on machinery and plant?

When machinery and industrial plant are running, loud noises often occur, which are not only an issue, but which can even be harmful to health over the long term. Large engines are moving parts generate vibrations, which transfer into the metal structures of the equipment and cause them to vibrate. These vibrations migrate as "structure-borne sound" through the machines and are emitted into the environment again – noise occurs. This drumming is amplified by the reflections on the hard walls and ceilings in factories. As several machines or plant are frequently located at one site, the noise level soon increases uncomfortably.

Metal constructions on large machines start to vibrate and transfer structure-borne noise. This is then emitted into the environment as air-borne sound and noise occurs.

When is noise insulation/ sound insulation necessary in machine construction?

The perception of sound and noise is always subjective, or in other words: Everyone perceives noise differently. What is tolerable for one person may already be a problem for someone else.

However, there are also statutory provisions, which regulate the use of sound insulation against noise, for example the machine noise protection ordinance. It applies to various equipment and machinery, from construction machines to construction and cleaning vehicles and garden and landscaping machinery. Together with the workshop directives and the generally applicable provisions for reasonable soundproofing, it regulates the use of noise insulation on machines. So a noise level (sound pressure level) of 80dB must not be permanently exceeded, otherwise there is an increased risk of heart and circulatory illnesses and hearing damage.

In order to prevent health problems, to lower the stress load and to increase productivity, targeted measures for hearing protection and sound insulation should be taken.

Above a certain sound pressure level, ear defenders are statutorily prescribed at the workplace. Effective soundproofing on machinery and plant helps to prevent noise.

What are the possibilities for retrofitting sound insulation to machines?

First of all it is important to identify the source of the noise. For often it is sufficient just to insulate individual components such the engine or the transmission of a machine with sound insulation mats.

Soundproofing individual components

If only specific components cause the noise and vibrations are not or are only slightly transferred to the machine, dampening these is sufficient. Sound insulation for individual components can be fitted to the existing cladding or casing around the machine using our self-adhesive aixFOAM sound insulation elements. In most cases this is enough to lower the noise level considerably.

Frequently, it is only certain components of a machine that generate vibrations and noise. Noise can be reduced by sound insulation on individual components, otherwise sound insulation is sensible on the entire machine.

Sound insulation on the entire machine, machine casing and sound insulation container

If several components add to the development of the noise and generate material vibrations, it is advisable to insulate the entire machine. The cladding already fitted here can also be used for attaching acoustic elements or a separate casing can be built for the machine. In most cases, plastic, metal or wooden casings are erected around the machine. In some cases, metal sound insulation containers are also used, which should also insulate the machine. There is also a risk of internal vibrations as a result of the low mass of the material. In order to prevent this, the casing should also be fitted with sound insulation panels.

For anti-drumming and to reduce vibrations, the material of the casing must be reinforced. Acoustic elements with a high density, such as heavy acoustic foil, heavy acoustic foam or ideally a combination of both elements, are particularly good. Alternatively, all aixFOAM sound absorbers can already be given a lamination made from heavy acoustic foil in the factory. Simply select the corresponding option in the configurator.

Noise insulation on compressors and lifts

Compressors and lifts represent a particular challenge for soundproofing/ sound insulation of machinery and plant.

Sound insulation on a compressor

Compressors are among the most noise-intensive machines in industry and labour. Frequently only the right soundproofing can ensure the permitted sound pressure level for these machines. Specific casings, which are fitted with sound insulation mats, are used for this. Nubbed foams and sound insulation mats with liquid-repellent surfaces are preferred, which adjust individually to the shape. In any case, when using sound insulation on compressors, it should be ensured that there is sufficient ventilation for the machine in order to prevent danger from heat development.

Nubbed foams with a high fire protection class are ideal for sound insulation on machines such as compressors or other technical equipment.

Sound insulation for lifts

Shafts for cargo and person lifts are frequently directly adjacent to living areas or workplaces. Architects and lift builders therefore have to observe the general conditions on noise insulation in high-rise buildings (DIN 4109) and the prescribed limit values and sound insulation measures (VDI 2566). Our aixFOAM sound insulation elements, which correspond to the fire protection standard DIN 4102B, are a good choice for less noise in the lift shaft.

Soundproofing for ventilation systems and air-conditioning

The soundproofing of technical building facilities such as air-conditioning or ventilation systems is particularly challenging because they not only generate noise, they also transport it.

For noise sources such as power units or generators, the construction of a casing around the device is recommended in order to stop the spread of air-borne sound. To this end, a casing can be erected around the device, which is then fitted with sound insulation mats. Porous absorbers such as the FLAT Tec with smooth surface or the MAYA Tec with trapezoid profile are suitable for this. For the casing, ensure that there is enough distance from the power unit or generator in order to guarantee the ventilation for the device.

In addition, the casing as well as the generator / power unit should ideally be decoupled from the floor or walls, i.e. that the walls of the casing or the power unit should not have direct contact with these construction elements. A special rubber sealing tape or an underlay heavy acoustic foam is suitable for decoupling. In order to distribute the device's weight consistently, the heavy foam should also be covered with a wooden panel.

The far-reaching ventilation pipes and air-conditioning ducts of technical building facilities transport structure-borne sound if there is insufficient soundproofing. As a result, noise can spread from room to room within a building. Disturbing noises also easily penetrate the inside of the building from the outside or are transmitted from the building to the surrounding area. This can quickly lead to problems with neighbours, irrespective of the development area. In order to prevent this, heavy acoustic foam can be used as anti-drumming for the pipes or they can be wrapped with sound insulation mats.

Large metal constructions and lightweight casings turn ventilation and air-conditioning ducts into sound conductors. Retrofitting soundproofing helps block the transmission of structure-borne sound and prevent drumming in the systems.

Sound insulation in the area of energy generation

Ever more plants for generating regenerative energies are being built. In particular, wind farms are noise producers as well as electricity generators. Heat pumps also generate noise and because of their proximity to residential buildings – like a cogeneration plant – are a challenge for sound insulation.

Soundproofing wind farms

Noise is generated at several locations on wind farms. While the noise caused by the wind swirling around the rotor blades cannot be dampened, the technical components such as motors and transmissions, which also generate noise, can be insulated with suitable sound absorbers. A separate casing around the noise components may also be sensible here.

Sound insulation for heat pumps and cogeneration plants

Heat pumps and cogeneration plants are mostly located in built-up areas and generate low-frequency, high-energy sound that easily penetrates into neighbouring houses and adjacent buildings. Retrofitting soundproofing of these energy plants is therefore particularly sensible. The most effective option is sound insulation here through separate casing of the noise-intensive motors and power units. Alternatively, the existing casting can also be fitted with sound insulation panels.

Energy plants such as wind farms, heat pumps and cogeneration plants are not only sources of electricity, but unfortunately also noise. It is therefore helpful to retrofit sound insulation to these plants.

You have the choice: Individually made sound insulation or standard solutions for machinery and plants

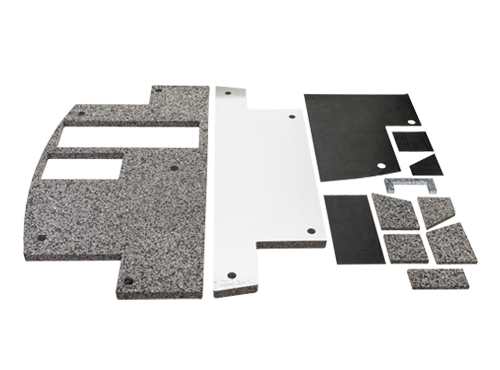

As a manufacturer of high quality sound insulation elements made from acoustic foam, we at aixFOAM know that sound insulation on machines is an extremely complex and individual subject. Many machines are tailored to the respective requirements of production and thus are special products. We therefore offer tailored parts for sound insulation on machines alongside the standard sound absorbers in panels.

Production

standardised or

individual

Surfaces

profiles to

choose from

Heights

different heights

can be selected

Installation

multiple

options

Fire protection

in different

classes

Protection

against dirt

and liquids

Our state-of-the-art manufacturing technology allows the custom-made production of special contours for fitting into existing housings and machines. We offer large, medium or small series as well as a standard range of modular acoustic absorbers for the sound insulation of machine cladding and the sound insulation of sound insulation hoods. On request, we can also produce prototypes for your planned soundproofing solution.

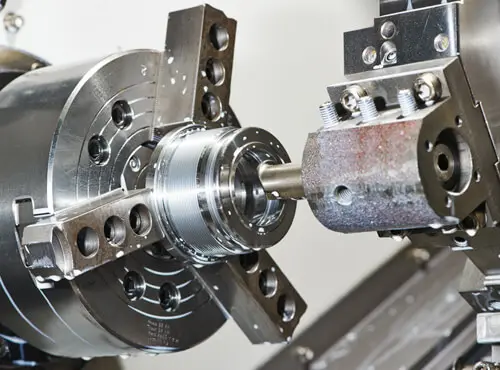

With state-of-the-art, high-precision CNC technology, we can produce individual soundproofing for your machines and systems. This makes it possible to produce both small and series production of soundproofing components for mechanical engineering.

aixFOAM impresses with brand quality - machines soundproofing “Made in Germany”

Through 60 years of experience and continuous optimisation of our high-quality acoustic foams, we have succeeded in developing flexible and robust soundproofing elements with high absorption values. aixFOAM sound absorbers reduce noise and structure-borne noise and are available in different fire protection classes and material thicknesses. Choose your favourites from several colours and surface profiles. Various surface laminations make aixFOAM sound insulation elements resistant to liquids and dirt and the practical self-adhesive equipment facilitates assembly even in demanding places.

Now it's your turn: Stop machine noise!

Choose your soundproofing from our aixFOAM products for mechanical engineering or use our free consulting service. Our experts will support you with your projects in order to find the right solution for your requirements. to find.

The aixFOAM technical planners can be contacted by telephone or email.

Free advice

Here you will find sound insulation for use in mechanical and plant engineering.

To the products