In this extract from an assembly video, we show you the cutting process step by step.

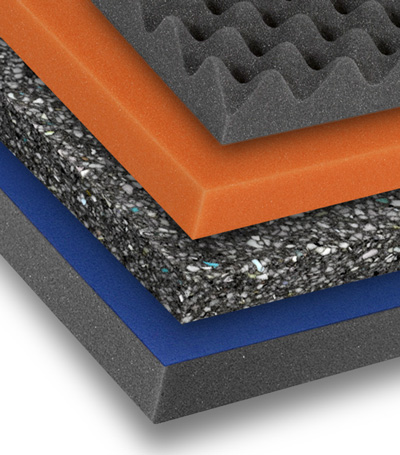

In general, all

aixFOAM sound absorbers made of

PUR foams (PUR-E, PUR-ES) and

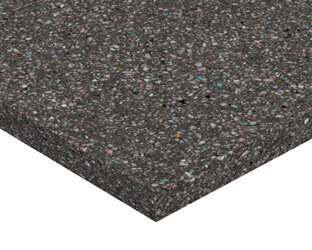

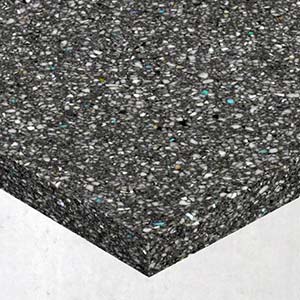

duromer acoustic foam (MH) can be cut easily and with little effort. A sharp cutter knife is usually sufficient to achieve a clean cut. With our HEAVY Duty sound insulation panels made of

acoustic heavy foam you may need a little more force. Therefore, please be particularly careful when cutting and pull the knife along your cutting aid (spirit level, squared timber, etc.) several times if necessary. The use of an electric knife can make work easier in this case.

Caution! Never use a tool with hot wire (hot wire cutter) to cut your sound absorbers, as is used to cut other insulating materials such as polystyrene. These tools work with high heat and scorch the material of your sound absorbers. Depending on the fire protection class, the sound absorbers may also be highly flammable.

In the

aixFOAM Shop you will find acoustic elements in various shapes and sizes. However, if you require a different format or special

cuts, simply contact us.

Contact us. We are of course available to answer any further questions you may have about the processing of your sound absorbers.