Sound insulation/ soundproofing of walls and ceilings

Sound insulation/ soundproofing of walls or ceilings is generally about lowering the sound pressure level and reducing noise. For this purpose, sound absorbers made of acoustic foam can be used. Acoustic elements made of this special foam have an open-pored structure that allows sound waves to penetrate deep into the material and absorb noise.

Various factors must be taken into account when selecting the appropriate materials and when installing the sound insulation on the wall or ceiling. First, it is necessary to look at where the disturbing source of noise is located. A distinction must be made between whether the noise source is in the same room or in an adjacent room. For example, fitting a rehearsal room so that music cannot leak to the outside or soundproofing a wall to prevent disturbing noise from the neighbours makes a difference.

Noise due to poor room acoustics

If the noise is due to poor room acoustics, e.g. because noise becomes layered due to long reverberation times or sound is reflected from walls and ceilings, targeted acoustic treatment measures should be taken. For this purpose, wall and ceiling surfaces are partly equipped with sound absorbers in order to absorb impacting sound or only certain frequency ranges. This improves the sound in the room, reduces acoustics more clearly and reduces noise. Detailed information on acoustic treatment for walls and ceilings can be found in our article “What is acoustic treatment?”.

Which materials are suitable for sound insulation/ soundproofing of walls and ceilings?

Isolating noise from another room, preventing sound from leaking and finding the right soundproofing solution is much more complex. In this case, we are talking about soundproofing. Soundproofing materials block or absorb incident sound as completely as possible. This prevents the ceiling or wall from becoming a sound conductor. Therefore, as a rule, only a full-surface covering of these components with sound absorbers can ensure sufficient soundproofing.

When selecting the right materials for soundproofing, it is crucial to know which form of sound needs to be isolated and where the disturbing sound source is located.

Sound insulation for noise leakage - blocking airborne sound

In order to prevent noise from leaking into adjacent areas from a room, the airborne sound must be blocked before it hits the wall or ceiling and then travels as structure-borne sound through these components to a neighbouring apartment or to the outside.

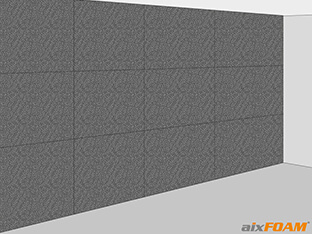

A full-surface wall or ceiling covering with the planned sound absorbers featuring a material thickness of at least 5 cm makes sense for this. When using lower thicknesses, it probably isn’t possible to achieve the desired effect in the medium and low frequency ranges. In practice, our FLAT or SMOOD quad absorbers have proven themselves as broadband absorbers on walls and ceilings.

Soundproofing with acoustic wall covering

High-performance soundproofing for walls meets high-end interior design:

Learn more about the soundproofing of a wall using an acoustic wall covering in our aixFOAM Knowledge Base article. This creative complete solution enables noise to be prevented from leaking to the outside using soundproofing, but also offers a high-quality alternative to the ordinary wallpaper.

Read more

Internal soundproofing - structure-borne sound suppression

If, on the other hand, noise needs to be prevented from leaking in from a neighbour, the structure-borne sound must be blocked before it actually becomes audible as airborne sound within your own home.

In order to insulate walls and ceilings against sound, soundproofing panels with a high dead weight are required, as these absorb material vibrations and interrupt the sound transmission. Sound insulation panels made of heavy-duty acoustic foam, installed in a soundproofing shell, are particularly suitable for this purpose.

In the following we have shown for you the step-by-step sound insulation of a wall using a shell construction.

Soundproofing of a wall with a shell construction - that's how it works!

This method of soundproofing of a wall is always suitable when it comes to blocking noise from an adjacent area, for example from the neighbour.

When soundproofing a wall using a shell construction, also referred to as a room-in-room concept, a second wall (shell) is erected in front of the wall being soundproofed. This is installed as a drywall construction in front of the existing solid wall. The soundproofing shell consists of a supporting metal stand consisting of profiles, sound insulation boards made of acoustic foam and plasterboard planking. For internal soundproofing, we recommend our heavy acoustic foam SH007 with a thickness of 5 cm. The soundproofing material is available in our aixFOAM shop.

Step 1: Preparation of sound insulation

For successful sound insulation, thorough planning is necessary in advance. The most important thing in soundproofing a wall using a shell construction is that the shell is completely decoupled from the solid wall and thus no sound transmission can take place. This means that the stand must not be connected to the solid wall, but must be anchored to the floor, ceiling and adjacent walls.

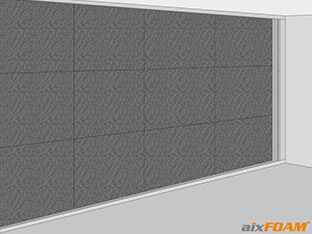

Step 2: Attach soundproofing mats

If sound strikes a wall, it vibrates and transmits the sound. This is known as structure-borne noise. To stop the vibrations and thus the transmission of sound, it makes sense to reinforce the structure of the wall. To do this, attach soundproofing panels made of acoustic foam firmly to the wall with total coverage. The practical self-adhesive backing of our aixFOAM soundproofing panels means this takes no time at all.

Step 3: Measure and mark

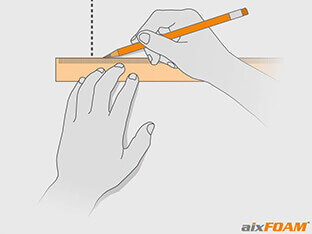

To prevent transmission of structure-borne noise, you should plan a distance of 2 - 3 cm from the solid wall for the shell construction. Use a spirit level to layout out the vertical course of the profiles and then mark their position for subsequent frame construction.

Step 4: Apply sealing tape

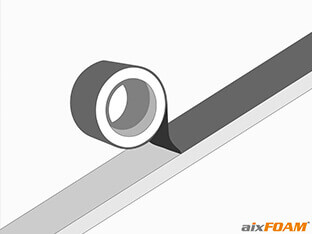

Commercial UW profiles (floor/ ceiling) and CW profiles (wall) from specialist dealers are suitable for the outer frame of the drywall. In order to use them to decouple the shell frame from the floor, the adjacent walls and the ceiling, we recommend sticking rubber profiles on the back of all profiles that come into contact with these components. The sealing tape prevents the profiles from coming into direct contact with the structure and prevents sound transmission.

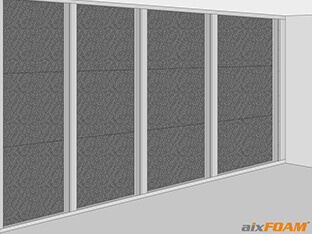

Step 5: Make profiles for frames

To create a stable frame for the shell construction, the profiles are screwed into the walls, floor and ceiling. Start with a UW profile on the floor and then insert a CW profile vertically into it. You can then simply place, align and fasten the UW profiles for the ceiling on the wall profiles. For a secure hold, drill the holes, drive in rotary pin anchors and then screw the profiles together using the cordless screwdriver.

Step 6: Position vertical profiles

As soon as the outer frame of the soundproofing shell has been built, the wall profiles can be adjusted vertically. You should choose the distances between the individual profiles according to the dimensions of your plasterboard. The distance should be large enough that half a plasterboard panel can be screwed to the profiles on the left and right.

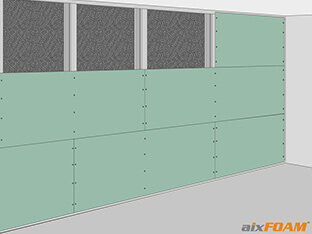

Step 7: Covering with plasterboard

Plasterboard panels are installed on the profiles. Make sure that the joints are offset by alternating with half a plasterboard on one side and a whole plasterboard panel in the row above. In order to avoid sound transmission through the floor and ceiling, the panels should not touch these components. Leave a distance of around 12 mm from the floor and around 5 mm from the ceiling. Self-tapping drywall screws with a fine thread are suitable for fastening.

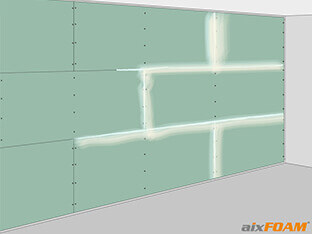

Step 8: Grouting the plasterboard

After you have installed all the plasterboard on the stud frame, grout the panel joints and screw heads. After drying, scrape off the edges and then use a spatula to apply filler to the panels.

Step 9: Seal wall connections

Use permanently elastic sealing compound to seal the wall connections of the shell. This has the advantage that it does not tear even after drying. Inject the sealing compound into the joints and complete the soundproofing. After a sufficient drying time, you can paint, clean or wallpaper the wall as required. Another tip: To prevent the sealing compound from coming into contact with the soundproofing panels, install insulation strips along the joints behind the sealing compound.

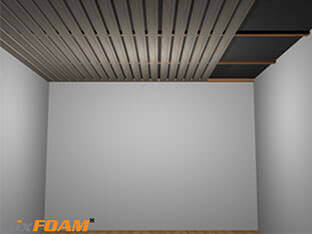

Sound insulation/ soundproofing for a ceiling

To soundproof a ceiling, we also recommend installing acoustic foam soundproofing mats with total coverage and then applying a secondary covering such as plasterboard or wooden ceiling planks. It is important that the support structure for mounting the covering is only installed on the ceiling with a properly designed vibration damping to prevent sound bridges. In other words: The ceiling should be “suspended”. Spring-mounted suspension systems (e.g. spring hanger hangers or acoustic swing hangers) are particularly suitable for this, as they resonate and thus neutralize the structure-borne noise.

Using our acoustic foam soundproofing panels enables a significant increase in the absorption of structure-borne noise to be achieved.

Please remember: Construction measures for sound insulation are comparatively difficult and particularly demanding when installing a suspended ceiling construction. Therefore, pay particular attention to occupational safety requirements or, if necessary, hire professional trade support.

With aixFOAM you will find the right products for soundproofing your walls and ceilings.

As acoustic experts with over 60 years of experience, we know: sound insulation of walls and ceilings is demanding and depends on many factors.

Fire protection for wall and ceiling soundproofing

With all acoustic measures, it is important to observe the applicable fire protection regulations. Our aixFOAM shop contains not only product recommendations and helpful information on absorption levels, but also the fire protection classes of the respective products.

We would also be happy to provide you with personal advice to find the right solution for your requirements. We're sure: with our diverse aixFOAM acoustic foams, you’ll definitely succeed in soundproofing ceilings and walls.