Soundproofing in the car, vehicle and vehicle production

Loud drumming, roaring and vibrating. Noise in the car, motor home, in classic vehicles, in commercial vehicles or agricultural machinery not only become annoying over the long term, they actually represent a health risk. But why is it often so loud in older cars and heavy vehicles, and what can be done about it?

What are the causes of noise in the vehicle?

Ambient noises, engine noises or road noise from the tyres are jointly responsible for an increasing noise level in the vehicle. In order to dampen this noise, vehicle manufacturers are investing lots of resources in soundproofing measures and in new technologies for noise suppression. However, the sound insulation is often insufficient especially in older vehicles or large commercial vehicles.

The reason for this is mostly found in the design of the vehicle itself. The drumming of the engine generates vibrations, which are transferred to the large metal constructions (e.g. doors, floor, roof) of the body and cause them to vibrate. If these construction elements are not sufficiently dampened, the vibrations migrate as "structure-borne sound" through the vehicle and then are emitted into the environment as loud drumming.

The large metal structures on vehicles, such as doors, roof and floor, start to vibrate when running and transmit structure-borne sound. This is then emitted into the environment as air-borne sound and noise occurs

Why is sound insulation so important when making vehicles and chassis?

Sustained noise in the vehicle not only impacts on the ambience, but also on the concentration and performance of the driver. In serious cases, this can become a safety risk. A permanent noise level above 85 dB increases stress, the risk of heart and circulatory diseases, and can lead to permanent damage to the hearing.

In the sense of works safety, and in order to prevent damage to health, noise insulation may also be relevant in commercial vehicles, agricultural and forestry machinery.

Soundproofing in vehicles helps to reduce noise. Above all, people that spend lots of time in the car or vehicle should ensure there is sufficient soundproofing in order to protect their health.

What are the options for retrofitting sound insulation in the car?

Firstly it is important to identify the source of the noise. For example, individual components such as the floor or separate areas such as the engine room, can be selectively soundproofed.

Soundproofing in the engine room

For soundproofing in the engine room, sound insulation panels with membrane absorbers are the first choice. The special foil on the surface, which lets through sound, protects the absorbers from splashes and oils. The panels can also be selected with self-adhesive kit on the reverse and thus easily stuck to the bonnet. In order to cover the panel transitions between the elements properly, we also recommend our aluminium tape.

Please note: aixFOAM products for sound insulation in vehicles comply with the usual fire class for car production, namely FMVSS 302 (DIN 75200). However, there should be sufficient space from the engine. Fitting sound insulation panels in the exhaust area and the area of the manifold is not recommended.

Anti-drumming in the chassis and floor

In order to minimise material vibrations and vibrations in the metal, it is necessary to reinforce the material so that it does not start to vibrate so easily. The heavy acoustic foam aixFOAM anti-drumming mats are particularly well suitable for these requirement. They have a high intrinsic weight, are extremely bendable and flexible. The heavy foil is also fitted with a practical self-adhesive surface as standard so that it can be stuck to the inside of the chassis quickly and easily. Additionally, the floor can be soundproofed with our heavy acoustic foam sound insulation panels.

Sound insulation for classic vehicles

For soundproofing in classic vehicles, our aixFOAM acoustic products are also recommended for floor insulation. The acoustic mats can be flexibly cut and laid and ensure more peace and comfort in the vehicle.

Driving fun without noise: Sound insulation panels stop the chassis drumming and insulate noise sources in the car. As a result they bring peace to older and classic vehicles.

How does soundproofing work in other vehicles?

Below we have summarised some information and tops for you about sound insulation in specific vehicles and machines.

Sound insulation for motor home and caravan

Apart from vibration noises and motor drumming, the soundproofing in the caravan or motor home also keeps ambient noise from the outside. If the sound insulation is poor, rain and hail hammering on the roof, or noises from the neighbours on the cap site can get on your nerves and spoil the holiday feeling. With our self-adhesive sound absorbers, you can quickly and easily soundproof the roof of your rolling home optimally. We therefore also recommend absorbers with a high surface weight, like our heavy acoustic foam, in order to stop the transmission of structure-borne sound through the walls and roof. For a maximum insulation effect, we advise laminating the heavy foam with heavy acoustic foil. You can choose this option easily in the product configurator.

Soundproofing in the motor home, caravan or trailer helps to insulation ambient noise – for a peaceful and relaxed holiday.

Soundproofing for lorries and special vehicles

As anti-drumming in the driver;s cabin, we recommend heavy acoustic foil in order to reinforce the cabin material and thus to stop vibrations and the transmission of structure-borne sound.

The aixFOAM sound absorbers with acoustic felt laminate or sound insulation mats with perforated artificial leather surface are suitable for soundproofing inside the driver's cabin. They are visually attractive, highly effective in sound absorption and washable. As the driver's cabin is often not only the workplace for the driver, but also their rolling living room, these absorbers are predestined for soundproofing in the lorry.

Our sound absorbers are also suitable for soundproofing in special vehicle production, soundproofing in trailer construction, soundproofing construction machinery or buses, and for insulation in train production. The same procedure as for anti-drumming of car chassis is also advisable for anti-drumming.

Quieter on the streets: The right sound insulation for lorries and special vehicles insulates noise from the vehicle and the environment. This helps professional drivers in their work.

Sound insulation for agricultural machinery, forestry machinery and commercial vehicles

They are large, have a number of vibrating components and powerful engines and transmissions: No wonder that tractors and farm machinery generate a considerable noise level and vibrations.

Apart from the classic heavy acoustic foil for anti-drumming of the chassis, our sound insulation mats with surface laminating are especially suitable for soundproofing agricultural or forestry machinery and vehicles. The aluminium membrane repels liquid, is oil-resistant and insensitive to the high dirt levels in agriculture and forestry.

For less noise when working, the retrofitting of soundproofing on agricultural and forestry machinery is sensible. aixFOAM sound absorbers for vehicle production are available with special surface lamination and thus are dirt resistant.

Fire protection and sound insulation in vehicle production – Fire protection class 302 (DIN 75200)

Our sound absorbers for technical soundproofing are available corresponding to the usual fire class FMVSS 302 (DIN 75200) in car and vehicle production. When selecting your sound insulation panels, however, please note the technical data regarding temperature resistance, which we have summarised for you on the article pages of the respective products. For extensive information, upon request we will be happy to send you the datasheets for our absorbers. Simply contact our customer service for this.

In order to keep the safety risk low when soundproofing vehicles, there must be sufficient space from the engine and other hot components, such as manifold or exhaust.

Why is aixFOAM sound insulation the best choice for soundproofing in vehicle production?

Through 60 years of experience and constant optimisation of our high quality acoustic materials, we have succeeded in developing flexible and robust sound insulation elements with high absorption coefficients.

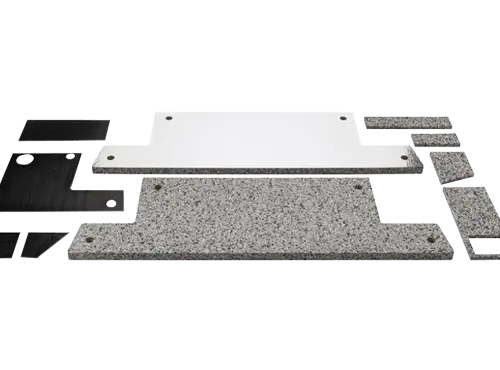

As a modern manufacturing company, we are not only able to offer you standard absorbers in panel shapes, but can also make individual contours for the perfect fit in vehicles and engines. Simply tell our service team your needs.

Your individually produced aixFOAM acoustic set for soundproofing in vehicle production: With the latest, high-precision CNC technology, we are able to make tailored sound insulation for your vehicles and engines.

aixFOAM sound absorbers reduce noise and structure-borne sound and are available in various fire protection classes and material thicknesses. Choose your favourites from several surface profiles. Different surface laminations make aixFOAM sound insulation panels resistant to liquids and dirt and the practical self-adhesive kit simplifies installation, even in difficult locations.

Production

standardised or

individual

Surfaces

profiles to

choose from

Heights

different heights

can be selected

Installation

multiple

options

Fire protection

in different

classes

Protection

against dirt

and liquids

Now it's your turn: Get the right sound insulation for your vehicle!

Now choose the right sound insulation from our aixFOAM products for the vehicle construction or use our free advice service. Our experts will support you with your projects and help you find the optimum solution for your requirements.

The aixFOAM technical planners can be contacted by telephone or email.

Free advice

This is where you can find the right sound insulation for the application in vehicle production.

To the products